VIO-200/PC100-EHL

The VIO/PC100-EHL series Power Efficient Panel PC are based on Intel® Celeron® J6413 processor.

Just The Right Touch For Automation

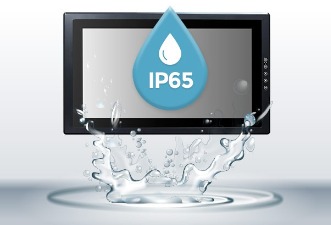

iCube's industrial touch display systems are patented and reliable products designed specifically for HMI automation, information and communication applications. The innovative modular design makes the display system more flexible and versatile by providing a unique solution for both an industrial panel pc or a touch monitor. With robust hardware engineering and tested rugged features, our industrial touch displays can easily withstand a wide range of extreme environmental challenges.

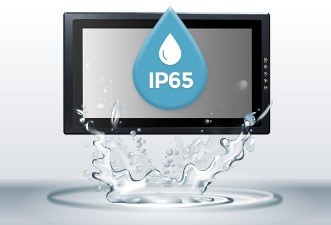

Our industrial touch display product line delivers a professional IP65 display solution with screen sizes ranging from 10.4" to 23.8" in both widescreen (16:9) and standard (4:3) aspect ratio. In addition, our industrial displays support the most common touch technologies including Projected Capacitive (PCAP) and Resistive. Learn more about iCube's Industrial All-in-One Panel PCs and Display Monitors below by checking out our 200 Series.

Easy Installation & Maintenance

Less Application Development and Validation Time

Zero Downtime and Upgrades

Easy Customization

Long-Term Reliability

High Flexibility And Scalability

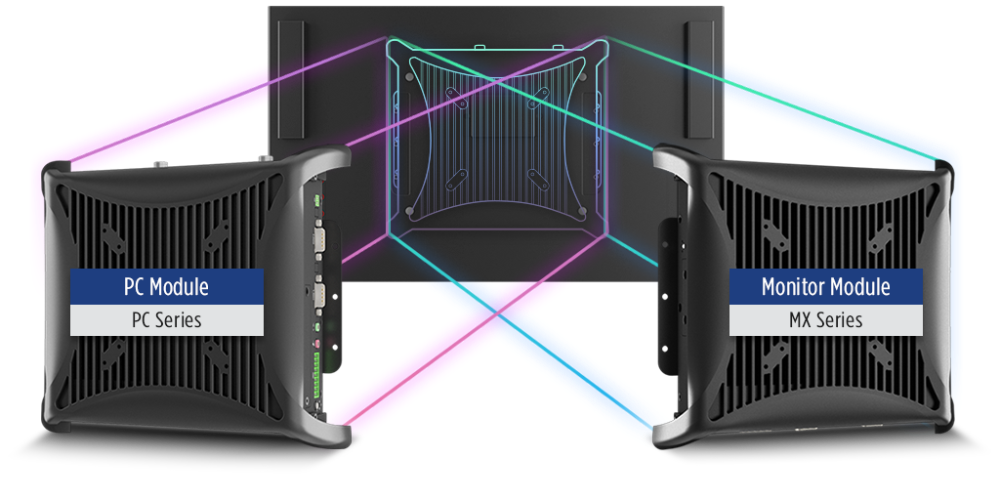

MDM stands for Multi-Mode Display Module. This iCube's patented modular design technology is fully optimized to iCube's industrial all-in-one VIO panel PC. VIO series offers a display module bundled with either an embedded PC unit or a display control module for optimal flexibility and scalability.

iCube’s patented Multi-Mode Display Modules (MDM) streamline industrial HMI and remote display deployments.

Available options include 1,000+ nit high-brightness panels to aid readability. Operating under extreme sunlight conditions may impede a display’s visibility. The high-brightness display option for rugged panel PCs and touch monitors boosts overall display visibility in glaring environments. Ideal for outdoor applications such as in-vehicle displays, outdoor kiosk machines and digital signages.

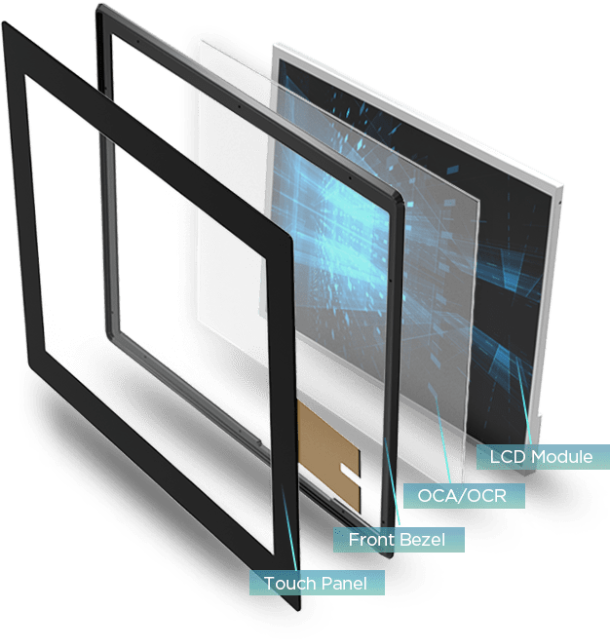

Optical bonding technology refers to the process of injecting a resin in-between the touch glass and the LCD display to enhance the readability and durability. Optical bonding option sustains clarity and vibrancy of the display under high humidity or bright sunlight conditions. The elimination of an air gap between the cover glass and display keeps out dust and moisture, which prevents condensation on the display’s surface. Additionally, optical bonding increases display contrast and readability in bright ambient environments by reducing the internal reflection between the cover glass and display. Optical bonding option is ideal for applications such as in-vehicle displays, public digital signages and outdoor kiosks.